Introduction

Cleaning and sealing concrete pavers can rejuvenate the appearance of any outdoor space, whether it’s a new project or an existing one. However, the process requires careful attention to detail to ensure optimal results and longevity. In this guide, we’ll delve into the dos and don’ts of cleaning and sealing concrete pavers, highlighting common pitfalls and offering professional advice to help you achieve stunning outcomes.

Common Problems with Sealing Pavers & Cleaning Pavers

Improper Cleaning Techniques

Cleaning pavers is the foundation of any successful sealing project. If you seal your concrete pavers without properly cleaning them, you run the risk of sealing in stains – potentially making them even more noticeable as well as impossible to remove. While DIY methods might seem convenient, using inappropriate cleaning agents, tools, or techniques can lead to undesirable outcomes.

Pressure Washing Misuse

Pressure washers can quickly and effectively remove surface dirt, debris, and even stains, but they aren’t always the best choice for cleaning pavers. Used improperly, pressure washers can damage patio pavers by removing joint sand and breaking down the surface layer of the pavers, exposing sublayers to moisture and environmental contaminants. Pressure washing can also drive debris into the pores of the cement instead of removing it, leaving unsightly pressure washer marks on pavers. Plus, these powerful tools have the potential to damage siding, outdoor lighting, landscaping, etc. with just one wrong move.

Using the Wrong Cleaning Agents

Professional-grade cleaners are essential to ensure thorough cleaning without damaging the surface, and your unique pavers and their current condition will determine the type of cleaning product you need. Photo by SRW

Chemical washing is critical to properly cleaning pavers’ surface while opening the pores of the concrete, facilitating a strong bond between the sealer and the surface. However, not all cleaners are created equal. Some DIYers attempt to use hydrochloric acid or muriatic acid to clean a surface prior to sealing. These acids are very concentrated and can damage the surface if you are not an expert with dilution rates or application methods. Professional-grade cleaners are essential to ensure thorough cleaning without damaging the surface, and your unique pavers and their current condition will determine the type of cleaning product you need.

Inadequate Preparation

Beyond choosing the correct general surface cleaner prior to sealing pavers, such as SRW’s PW, EF, or DW, you may need to perform spot cleaning. General cleaners may not be able to tackle major discolorations, and if you fail to address these before sealing patio pavers, you could be stuck with them.

Start by spot-cleaning pavers anywhere there is major discoloration using a specialty cleaner from SRW. Be sure to select a cleaner that is formulated for the type of stain you are treating, as not all cleaners work the same way. Rust stains, for example, require a different cleaner than mold and mildew stains.

Always test all cleaners and sealers in an inconspicuous area to ensure that you will achieve the desired results on your specific pavers.

Sealing Too Soon

If you are sealing a new installation for the first time, always follow your paver manufacturer’s recommendations regarding the appropriate curing time for their product. Manufacturers often recommend waiting several months to a year before sealing concrete pavers. This is because concrete paving stones contain natural minerals that rise to the surface through a process called efflorescence. It can take some time for these minerals to work their way out of newly installed paving stones. Sealing the stones too soon can trap the paver efflorescence, creating a splotchy appearance.

Over-Sealing

Resealing pavers too often can result in a hazy or splotchy appearance. Paver sealer should typically be reapplied every 3-5 years. You should be able to see a color change when the sealer begins to show signs of wear.

Incorrect Application

Neglecting to follow the manufacturer’s instructions is a common pitfall in cleaning and sealing projects. Whether it’s preparation, application techniques, or temperature considerations, deviating from the recommended guidelines for your specific pavers can lead to subpar results and potential damage to the surface. Missing a step or finding a faster method can create issues that significantly increase time spent working on the project.

Tips for Successfully Sealing Pavers

Choose the Right Products

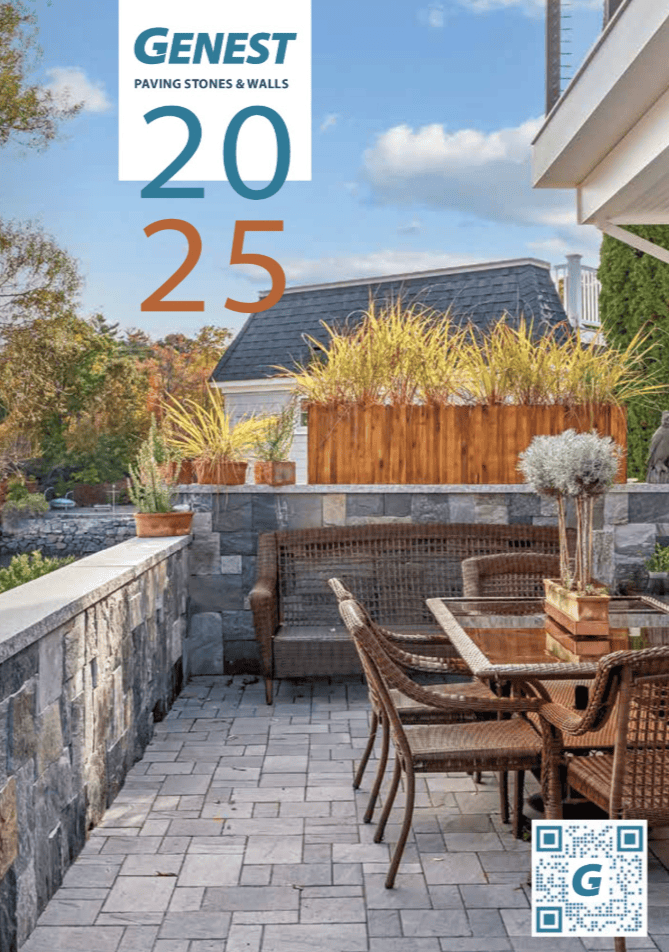

Check with your paver manufacturer for the appropriate sealers and cleaners, and follow the application guidelines. Genest recommends Paver Seal from SRW Products, and we carry a variety of options at our three retail locations to best suit your patio material and preferences. Typically, sealers come in two finishes: film-forming or penetrating. Penetrating sealers tend to retain more of the natural look of the pavers, while film-forming sealers form a protective barrier over the surface, typically darkening the color of the pavers and providing a high-gloss or low-gloss appearance.

Follow Professional Advice

For a seamless and successful sealing project, adhere to the following principles:

- Always use an appropriate surface cleaner before sealing pavers.

- Wait the recommended time before sealing concrete pavers, and ensure that the surface is completely dry prior to application. This could take several days after cleaning.

- Know the weather and temperatures during and after application, avoiding rain and extreme temperatures. If the recommended temperature range is not maintained, the sealer may not adhere properly, and you must allow sufficient curing time before exposing the surface to moisture. Don’t rush the job, especially if weather conditions are uncertain.

- Whether using penetrating or film-forming sealers from SRW, always apply with a sprayer for even coverage and backroll with a slit foam roller to ensure uniform coverage and prevent the sealer from pooling in the texture of the surface.

- Always read and understand product instructions, seeking guidance from professionals if needed.

- When in doubt, hire a professional.

Conclusion

Cleaning and sealing concrete pavers can transform outdoor spaces, enhancing aesthetics and durability. By avoiding common pitfalls such as using inappropriate cleaning methods or neglecting product instructions, and by following professional advice, you can achieve exceptional results that stand the test of time. Remember, attention to detail and the use of quality products are key to a successful sealing project.